Pratt & Whitney’s Innovative DED Repair Cuts GTF Engine Repair Time by 60%

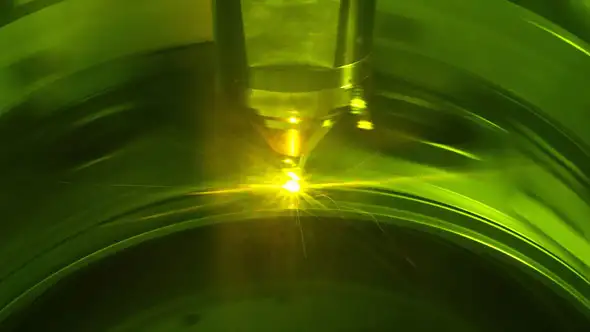

Pratt & Whitney, an RTX company based in East Hartford, Connecticut, has introduced a groundbreaking additive manufacturing (AM) repair solution for its GTF engine components. The new Directed Energy Deposition (DED) process slashes repair time by over 60% and is set to be implemented across Pratt & Whitney’s global GTF Maintenance, Repair, and Overhaul (MRO) network.

Pratt & Whitney, an RTX company based in East Hartford, Connecticut, has introduced a groundbreaking additive manufacturing (AM) repair solution for its GTF engine components. The new Directed Energy Deposition (DED) process slashes repair time by over 60% and is set to be implemented across Pratt & Whitney’s global GTF Maintenance, Repair, and Overhaul (MRO) network.

Revolutionizing Engine Repairs with Additive Manufacturing

The advanced DED technology simplifies the repair of structural case features on GTF engines by reducing multiple steps in the conventional process. Key improvements include minimized machine changeover and fewer heat treatment cycles. This innovation not only speeds up repairs but also lowers tooling costs and complexity, enhancing overall efficiency.

Pratt & Whitney estimates that this AM-based repair approach will save $100 million in parts recovery over the next five years. Kevin Kirkpatrick, Vice President of Aftermarket Operations at Pratt & Whitney, emphasized the benefits: “This agile repair process improves turnaround times for customers while easing material supply constraints. We’re also exploring additional applications for AM in other critical GTF part repairs.”

Collaborative Development and Future Applications

The DED repair solution was developed at Pratt & Whitney’s North American Technology Accelerator in Jupiter, Florida, in collaboration with the Connecticut Center for Advanced Technology and the RTX Research Center. Beyond structural repairs, the technology will also be used to restore components worn down through normal engine operation.

Expanding Technology Accelerators for Greater Efficiency

In April 2024, Pratt & Whitney announced plans to broaden its technology accelerator initiatives, incorporating advanced repairs, digital inspection, adaptive processing, and specialized coatings for compressor and fan parts. The North American facility complements the Singapore Technology Accelerator, launched in 2022, which focuses on robotics, digital twin technology, and smart factory solutions. Together, these programs are projected to deliver annual savings of at least $24 million.

A Robust Global MRO Network

Pratt & Whitney’s GTF MRO network spans four continents, featuring 20 specialized repair shops and additional quick-turn service sites. This network is part of the company’s EngineWise® program, offering operators flexible, cost-effective aftermarket solutions for long-term engine performance and sustainability.

With this latest advancement, Pratt & Whitney continues to lead in aerospace innovation, delivering faster, more efficient repairs while reducing operational costs and supply chain dependencies.